Ozosteril

Ozosteril

The Ozosteril® is a continuous process for the reduction of mycotoxins in dry and divided foodstuffs via ozone (O3) treatment.

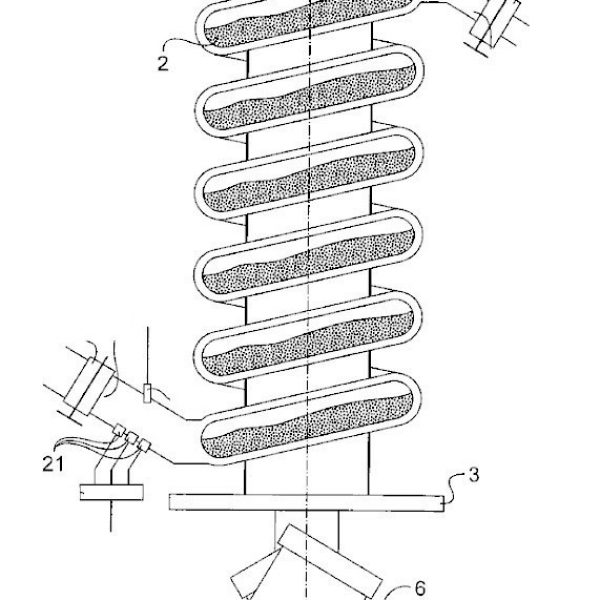

Its design is based on the unique, patented combination of a vibrating conveyor and an Ozone generator.

Ozone is the triatomic form of oxygen (O3). Ozone is generated by combining oxygen atoms (O) with oxygen molecules (O2). The corona discharge process takes place inside an ozone generator, between a high-voltage electrode and a ground electrode. When a high-voltage field is applied, a silent electrical discharge occurs in the gap.

This discharge agitates the oxygen molecules in the gas, causing them to break up and recombine with other oxygen molecules to form ozone.

Ozone is a powerful oxidant that destroys mycotoxins and pesticides.

The U.S. Food and Drug Administration has formally approved the use of Ozone as an antimicrobial agent for the processing, storage and manufacture of ingredients in aqueous or gaseous form.

This approval was published on June 26, 2001 (FDA, 2001).

Mycotoxins

- Aspergillus -> Aflatoxines

- Fusarium -> Deoxynivalenol (DON)

- Penicillium -> Ochratoxines

- Etc