STERILIZATION / PASTEURIZATION

In dry ingredients such as cereals, spices, herbs or flours, contamination occurs from cultivation, harvesting or drying at producers. It is highly dependent on climatic conditions and technical means, sometimes very basic for the smallest farms.

Cooperatives or processing industries receive batches of very variable qualities, which must be thermally treated before commercialization and customer use.

It is having this in mind that ETIA created Safesteril® in 1998, a continuous thermal process of microbial decontamination for divided solids.

THE PROCESS

Our Safesteril® technology is installed worldwide and famous for its efficiency on powdery products, from micronized powder to 5 cms particles.

Thanks to a homogeneous treatment due to a non-static exposure to steam and the non-condensation of this steam on the product, Safesteril® has a minimal impact on the color and other heat-sensitive properties.

Pathogens are entirely inactivated : yeasts, moulds, enterobacterias, coliforms, salmonellas and total plate count is greatly reduced.

Taste, color and humidity are preserved during the process and the volatile oil loss is lower than 10%.

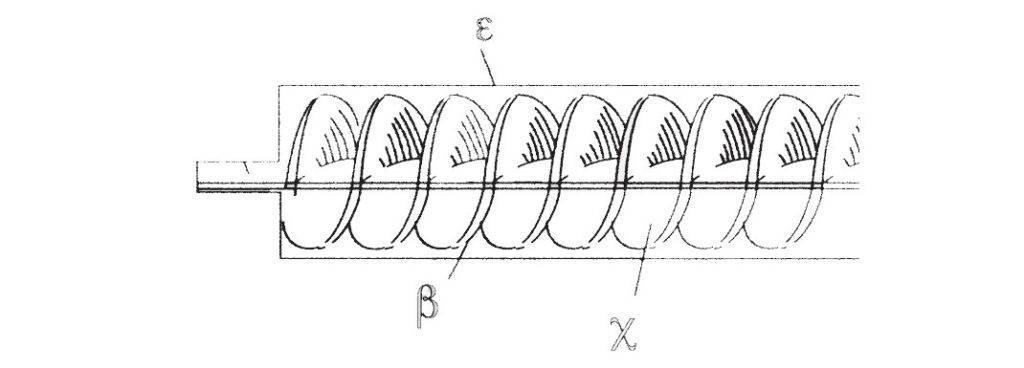

Design and instruments located on Safesteril® are allowing a real time treatment scale (time / temperature) which is applied to the product during his journey in our heated screw conveyor Spirajoule® and to automatically bypass any product that would not have been treated properly.

What can be safesterilized

SPICES

DEHYDRATED VEGETABLES

Nuts

Herbs

Cereals and flours

Cosmetics & Nutraceuticals

A tailored solution

Since every project is different, ETIA designs unique solutions adapted to your requirements and based on a technical evaluation that benefits from a Return Of Experience of multiple years.

The using of existing auxiliaries (steam, dry air, chilled water) required to this process is possible and will then reduce the capital investment of the global project.

Safesteril® models are covering a large range of capacities from 50 to 3,000 kgs/ hour (110 – 6,600 lbs / hour).

Let’s build together the project you need!

SUSTAINABILITY

Safesteril® is an ecological technology , and being concerned about environment and the savings of our customers, our systems are including :

- A 100% electrical energy

- A closed loop of cooling water, reducing water usage

- A chamber entirely insulated so that energy and steam consumption are reduced to the minimum required

- A valorization of the generated fluids

- An annual preventive maintenance program coupled with a warranty period of 1 year allowing a continuous technical availability of the process line

LOW MAINTENANCE

(1% OF THE CAPEX / YEAR)

We provide a free remote assistance service for the entire life of the machine.

GREEN TECHNOLOGY

(100% ELECTRICAL, FOSSIL-FREE)

Built on our patent using Joule effect and the first law of electricity : The Ohm’s law.

OPTIMAL CLEANABILITY

(With an access to any machine part)

A global cleaning is possible thanks to a large door access making easy the access