Cooling

Cooling

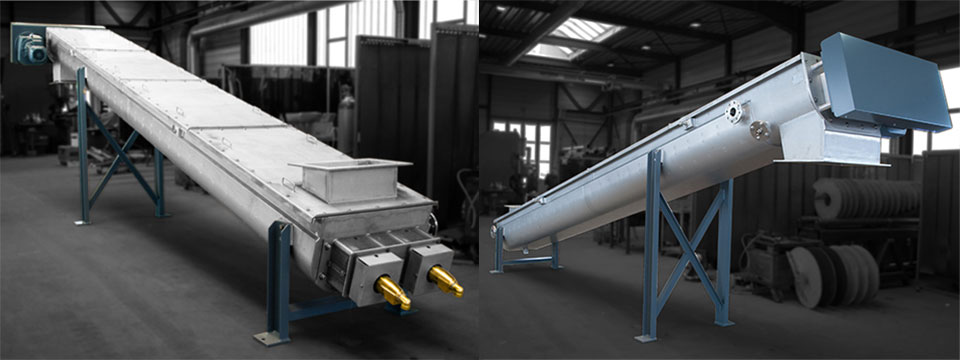

After manufacture, many products need to be cooled to the ideal temperature before further processing.

The product passes through the screw spiral and is gently transported to the outlet. A double-jacket system allows the cooled water to circulate without coming into direct contact with the product.

The cooling screws are equipped with a cooled trough and shaft, enabling the desired temperature difference to be achieved through indirect cooling, while optimising the exchange surface area, thereby limiting the overall footprint for the same efficiency. As a result, the optimum product outlet temperature is reached more efficiently.

THANKS TO OUR MANY YEARS OF EXPERIENCE IN HEAT EXCHANGERS, OUR KNOW-HOW AND OUR NUMEROUS INSTALLATIONS, WE ARE ABLE TO RESPOND TO ANY TYPE OF REQUEST.

Construction features :

- robust, modular construction

- lined

- dust-free transport

- gas- and pressure-tight

- easy cleaning thanks to full access to equipment parts

Applications :

- chemical

- food & beverage

- green tech, etc.

Conveyed products :

- bulk materials

- pellets

- powders

- pasty or sludgy products

Versions :

- steel

- stainless steel

- wear-resistant steel